Baking and Vacuum packing

Action Circuits have the facility to moisture bake and repackage electronic devices. We can bake any vacuum pack electronic devices as required, however industry standard times and temperatures range from 6 hours at 125deg C to 24hrs at 125deg C. Equally we can carry out a 12hr bake or a 6hr bake, or at a reduced temperature for longer periods.

In surface mount technology (SMT), semiconductor devices are soldered on to the surface of PCB’s, using processes that expose the devices to temperatures between 210 C and 260 C, for a relatively long time (4 to 60 seconds). Due to this high temperature shock, in the early period of SMT a wide number of Surface Mount Devices showed severe damage after the process. The largest PLCC and SO devices could explode like popcorn, and this phenomenon became known as the popcorn effect. Devices are now produced using packaging techniques to avoid this effect, however moisture retention in the package can still cause excessive mechanical stresses during the soldering process, causing cracks and delaminating. In some cases when this damage affects critical areas, long term reliability may be compromised.

Although new moulding compounds have been developed by the semiconductor industry, in a number of SMD’s it is still necessary to control the moisture content in the encapsulation, upto the moment that they are submitted to the soldering process.

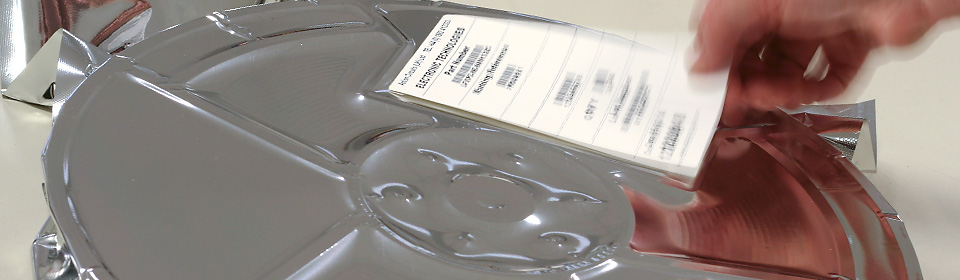

This control is obtained by shipping and storing sensitive SMD’s in moisture barrier bags. They are hermetically sealed and can control the moisture absorption from the ambient environment, thus maintaining the devices in a dry condition until used.

A major point is to quantify the shelf life of the device once it is removed from the sealed bag. This is a most important consideration when processing devices prior to assembly (soldering). If the devices have been exposed for longer than the specified time, it is essential to use our component baking and vacuum packing service to certified that the components are safe to store and use.

Our component baking and vacuum packing procedures are based on the EIA JEDEC standard JESD22-A112, and International Standard STD020, which define six levels of moisture sensitiveness.

At Action Circuits we operate very strict component handling procedures, which incorporate dry packing / moisture control systems to ensure that all device exposure time is recorded.

To learn more, contact us here.

Action Circuits (UK) Ltd,

Action Circuits (UK) Ltd,